Large Diameter DTH Drill Pipes

- Applicable hole diameter: 305-1200mm

- Thread connection types: NUMA 120/180/240; API REG

- Material: Low-carbon alloy steel

Request a Quote

Typical Applications

Rock socket drilling in foundation engineering projects, including building piles, bridge piles, metro construction, and other infrastructure foundation works.

Technical Specifications

| Model | Outer diameter | Adapter type | Length |

| |

426mm | 273 hexagonal | 1000-9000mm |

| |

450mm | 273 hexagonal | 1000-9000mm |

| |

508mm | 273 hexagonal | 1000-9000mm |

| |

610mm | 273 hexagonal | 1000-9000mm |

| |

711mm | 320 hexagonal | 1000-9000mm |

| |

813mm | 320 hexagonal | 1000-9000mm |

| |

914mm | 320 hexagonal | 1000-9000mm |

Key Advantages

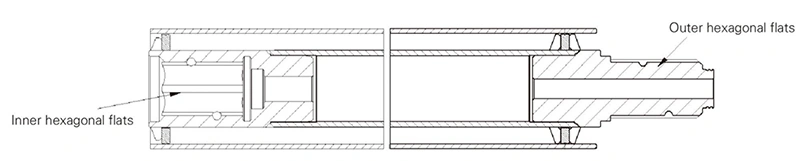

- Excellent interchangeability: All connections are designed according to NUMA-standard hexagonal joints, ensuring high interchangeability with mainstream large-diameter DTH systems.

- Customizable length range: Drill pipe lengths can be customized from 1m to 12m, allowing flexible configuration to suit different drilling depths and rig setups.

- Hexagonal quick-connection design: The hexagonal male-female joint design significantly reduces make-up and break-out time.

- Due to the heavy weight of large-diameter drill pipes, installation is typically assisted by a crane. Once the hex joint is properly aligned, the pipe is secured with a locking pin, enabling fast, safe, and reliable installation.

- Excellent air sealing performance: The drill pipes provide reliable air sealing with minimal leakage, making them well suited for DTH drilling operations using high-capacity air compressors.

- Optimized pipe diameter for air efficiency: The pipe diameter is designed to closely match the drill bit diameter, improving air utilization efficiency during drilling and reducing compressor air consumption, thereby lowering overall operating costs.