Large Diameter DTH Drill Bits

- Applicable hole diameter range: 305-1200mm

- Face designs: flat face, convex face, concave face, double-row button face, center-drop face

- Button types: domed button, semi-ballistic button, ballistic button, pointed button, flat button

Request a Quote

Typical Applications

Embedded installation methods for precast piles, CFA (continuous flight auger) rock-socketed piles, bored piles drilled into rock formations

Technical Specifications

| Model | |

|

|

|

|

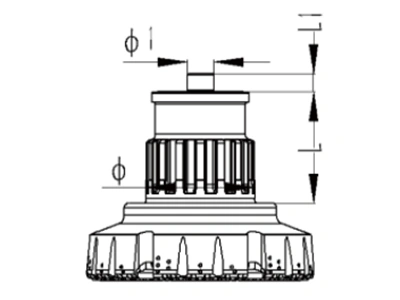

| Length, L | 260mm | 258mm | 324mm | 321mm | 355.8mm |

| Diameter,Ø | 67mm | 82.5mm | 102mm | 118mm | 164.5mm |

| Length, L1 | 54mm | 54.5mm | 53mm | 57mm | 60.3mm |

| Diameter, Ø1 | 26mm | 32mm | 36.4mm | 41mm | 56mm |

| No. of splines | 8 | 8 | 8 | 8 | 8 |

| Recommended hole size | 105-130mm | 135-152mm | 155-190mm | 203-254mm | 245-305mm |

| Shank model | DHD112 NUMA120 SD12 QL120 | NUMA125 M140 | NUMA180 | NUMA240 | NUMA280 |

Key Advantages

- High-strength bit body: The large-diameter bit body is manufactured from high-strength alloy steel, providing excellent resistance to cracking and body breakage under high-impact drilling conditions.

- Non-destructive inspection (NDT): Ultrasonic testing and magnetic particle inspection are applied to the bit body to eliminate material and forging defects, significantly reducing the risk of in-service failures.

- Oversized carbide buttons: Enlarged carbide buttons are used to extend wear life and enhance rock-breaking efficiency, improving overall drilling performance.

- Precision CNC machining: CNC machining of the bit body ensures high dimensional accuracy, reliable assembly, and consistent product quality.

- Reinforced skirt design: A specially engineered high-strength, high-toughness skirt enhances structural integrity and ensures stable performance under severe impact and torque loads.

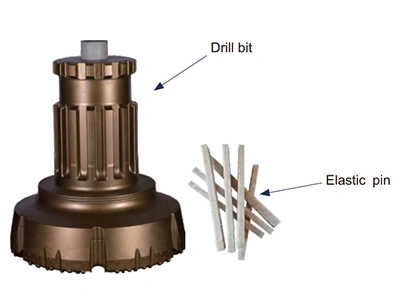

- Spline shock-absorption design: The spline interface is integrated with damping buffer elements, reducing impact fatigue and significantly extending spline service life.