Casing Advancement Systems

Drilling systems for casing advancement in overburden formations

Casing advancement systems combine the high penetration efficiency of down-the-hole hammer drilling with simultaneous casing installation. This approach improves drilling efficiency, reduces overall construction costs, and is widely applied in mine shafts and drifts, slope stabilization, geological hazard mitigation, dam foundation reinforcement, deep excavation support, structural uplift and overturning resistance, as well as cofferdam seepage control projects.

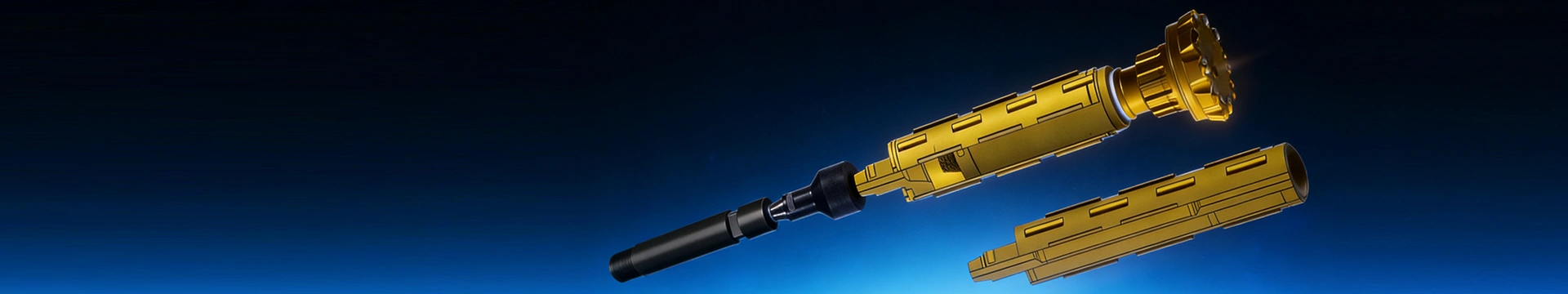

Component Display of the Integrated DTH System

Eccentric casing drilling systems are designed for overburden drilling where borehole collapse or instability may occur.

Concentric casing drilling systems with ring bits, wings, and blocks are designed for stable casing advancement in complex ground conditions.

The casing body is manufactured from high-quality R780 or P110 steel, while the threaded joints are made of premium 42CrMo alloy steel.

Casing shoes are designed for casing-supported drilling operations to stabilize borehole walls in foundation piling and water well projects.