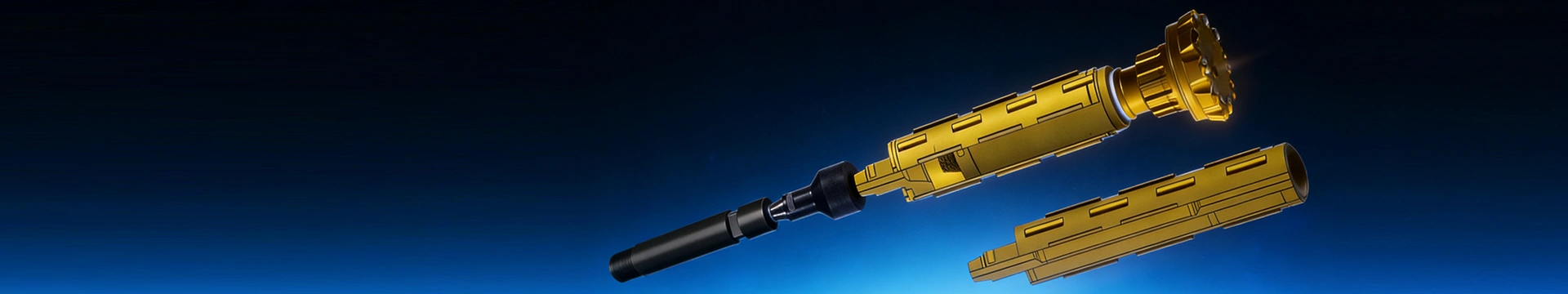

Oil Well Drill Pipes

Oil well drill pipes are the primary connecting components in oilfield drilling operations, linking the surface rotary system, hoisting system, and circulating system with the drill collars and drill bits.

Request a Quote

Through the drill string, rotary torque is transmitted from the rotary table to the drill bit, vertical movement is controlled by the hook system, and drilling fluid is circulated to the bottom of the well. This integrated operation enables continuous rock breaking, cuttings removal, and efficient drilling progress.

The products meet or exceed the requirements of: API SPEC 5DP, API SPEC 7-2, API RP 7G.

Typical Applications

Oil well drill pipes play a critical role in oil and gas drilling operations as well as geological exploration projects.

Technical Specifications

| Size | Nominal weight | Plain end weight | Wall thickness | Inner diameter | ||||

| mm | inch | lb/ft | lb/ft | kg/m | inch | mm | inch | mm |

| 60 | 2 3/8 | 6.65 | 6.26 | 9.33 | 0.28 | 7.11 | 1.815 | 46.1 |

| 73 | 2 7/8 | 10.4 | 9.72 | 14.47 | 0.362 | 9.19 | 2.151 | 54.6 |

| 89 | 3 1/2 | 13.3 | 12.31 | 18.34 | 0.368 | 9.35 | 2.764 | 70.2 |

| 15.5 | 14.63 | 21.79 | 0.449 | 11.4 | 2.602 | 66.1 | ||

| 102 | 4 | 14 | 12.93 | 19.27 | 0.33 | 8.38 | 3.340 | 84.8 |

| 15.7 | 14.69 | 21.87 | 0.38 | 9.65 | 3.240 | 82.3 | ||

| 114 | 4 1/2 | 16.6 | 14.98 | 22.32 | 0.337 | 8.56 | 3.826 | 97.2 |

| 20 | 18.69 | 27.84 | 0.43 | 10.92 | 3.64 | 92.5 | ||

| 127 | 5 | 19.5 | 17.93 | 26.7 | 0.362 | 9.19 | 4.276 | 108.6 |

| 25.6 | 24.03 | 35.8 | 0.5 | 12.7 | 4 | 101.6 | ||

| 140 | 5 1/2 | 21.9 | 19.81 | 29.52 | 0.361 | 9.17 | 4.778 | 121.4 |

| 24.7 | 22.54 | 33.57 | 0.415 | 10.54 | 4.67 | 118.6 | ||

| 168 | 6 5/8 | 25.2 | 22.19 | 33.04 | 0.33 | 8.38 | 5.965 | 151.5 |

| 27.7 | 24.22 | 36.06 | 0.362 | 9.19 | 5.901 | 149.9 | ||